One thing about being a furniture maker these days is that you tend to get commissions that are all over the place stylistically. Nineteenth Century rustic followed by mid Twentieth Century Modern, a built-in piece and then back to the Seventeenth Century. It’s hard to specialize in a particular style.

One thing about being a furniture maker these days is that you tend to get commissions that are all over the place stylistically. Nineteenth Century rustic followed by mid Twentieth Century Modern, a built-in piece and then back to the Seventeenth Century. It’s hard to specialize in a particular style.  Recently though, I have had back to back to back pieces in the Mannerist style. The style came to England in the late Sixteenth Century through Continental (European) artisans and pattern books. It was based on Northern European renaissance ideas of classical design which gives the pieces a naive quality. Roughly speaking there are two groups of Mannerist-style furniture in Colonial America ; a low relief carved strap-work variety and an applied ornament variety with deep moldings and architectural elements.

Recently though, I have had back to back to back pieces in the Mannerist style. The style came to England in the late Sixteenth Century through Continental (European) artisans and pattern books. It was based on Northern European renaissance ideas of classical design which gives the pieces a naive quality. Roughly speaking there are two groups of Mannerist-style furniture in Colonial America ; a low relief carved strap-work variety and an applied ornament variety with deep moldings and architectural elements.  I’ve got both types here, starting with this valuables cabinet based on the one the Symonds shop made for Joseph and Bathsheba Pope in 1679. It has the applied elements and the strap-work carving and is at once both crude and remarkably refined. The applied turnings and moldings really throw light around to dramatic effect, especially in low or raking light. Inside is an arrangement of drawers which I have dovetailed though the original has butted and nailed drawers.

I’ve got both types here, starting with this valuables cabinet based on the one the Symonds shop made for Joseph and Bathsheba Pope in 1679. It has the applied elements and the strap-work carving and is at once both crude and remarkably refined. The applied turnings and moldings really throw light around to dramatic effect, especially in low or raking light. Inside is an arrangement of drawers which I have dovetailed though the original has butted and nailed drawers.

The center medallion was typically carved with the owners initials. (this one is available, and can be carved to suit).

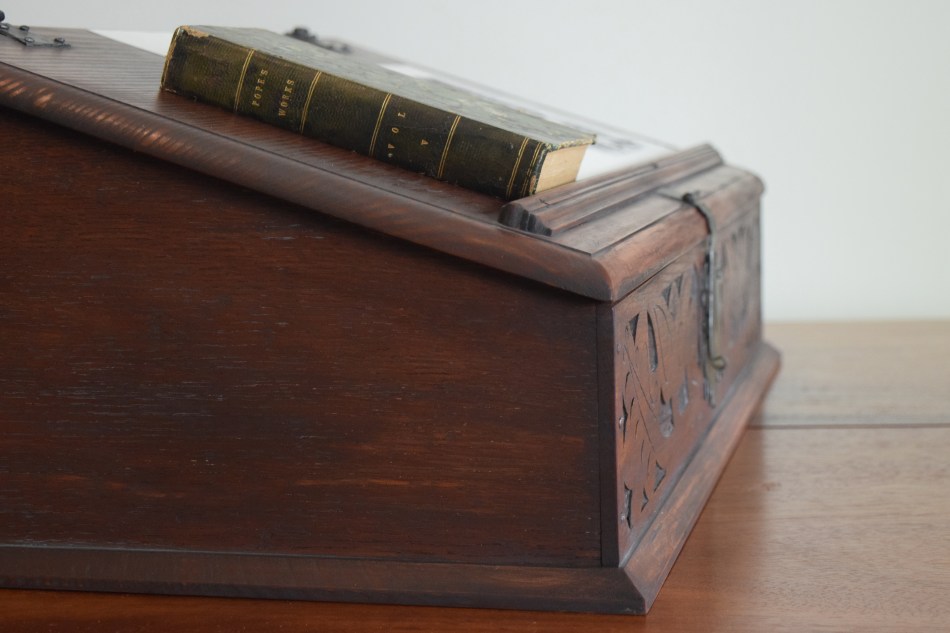

The center medallion was typically carved with the owners initials. (this one is available, and can be carved to suit). The next piece is a desk box I designed based on the Mannerist carved Hadley chest tradition of the Connecticut River Valley. Interestingly the Valuables Cabinet above could have been made by John Pease who later moved to the Hadley area and may have helped to start that school of carved furniture.

The next piece is a desk box I designed based on the Mannerist carved Hadley chest tradition of the Connecticut River Valley. Interestingly the Valuables Cabinet above could have been made by John Pease who later moved to the Hadley area and may have helped to start that school of carved furniture. In all, I’ve made five Mannerist style pieces this year and it has been great to soak in the period and try to get into the heads of these early masters.

In all, I’ve made five Mannerist style pieces this year and it has been great to soak in the period and try to get into the heads of these early masters.

The awesome hasp-lock on the desk was made by Matthew Stein. Below is another Hadley style trunk which is also available.

The awesome hasp-lock on the desk was made by Matthew Stein. Below is another Hadley style trunk which is also available. Lastly, I rarely post things on this “blog” but you can see more recent, up to the minute, or week, posts on Instagram at davidsantickdavid

Lastly, I rarely post things on this “blog” but you can see more recent, up to the minute, or week, posts on Instagram at davidsantickdavid

Latest

The Accidental Mannerist

Recent Work

This picture sums up where I am these days. Looking backward and forward, old and new. The Hadley trunk, based on examples from 1695-1725, I made of sassafras and finished with paint and shellac. It rests upon a minimalist and modern white oak breakfast table. The trunk is festooned with an ancient carving pattern complemented by an escutcheon cast from original 17th Century brasses. The corners are nailed like the original.

This picture sums up where I am these days. Looking backward and forward, old and new. The Hadley trunk, based on examples from 1695-1725, I made of sassafras and finished with paint and shellac. It rests upon a minimalist and modern white oak breakfast table. The trunk is festooned with an ancient carving pattern complemented by an escutcheon cast from original 17th Century brasses. The corners are nailed like the original.

The table is restrained, it is all about the form., the only decorations are the figure of the boards with which it is made. The finish is “dry” with a low shine that suits it perfectly. It’s modern and clean but approachable and warm, usable.

I’ve been bouncing back and forth between styles for the last 13 years, making custom furniture here at Antick in Lambertville, New Jersey. It’s never a straight line, but sometimes things relate to each other in style or species of wood. This year I’ve been making 17th Century case pieces or farm tables. Here are some of them.

I’ve been bouncing back and forth between styles for the last 13 years, making custom furniture here at Antick in Lambertville, New Jersey. It’s never a straight line, but sometimes things relate to each other in style or species of wood. This year I’ve been making 17th Century case pieces or farm tables. Here are some of them.

This cabinet is based on a piece at Winterthur in Delaware. It is made of walnut with excellent hardware from Londonderry. I really like the turnings and, though it’s hard to see, the x-stretcher between them.

This cabinet is based on a piece at Winterthur in Delaware. It is made of walnut with excellent hardware from Londonderry. I really like the turnings and, though it’s hard to see, the x-stretcher between them.

This is a farm table I designed in white oak with a plank top.

This is a farm table I designed in white oak with a plank top.

This valuables cabinet was particularly interesting. It is made of walnut with two figured tombstone paneled doors. Lots of great hardware and moldings.

This valuables cabinet was particularly interesting. It is made of walnut with two figured tombstone paneled doors. Lots of great hardware and moldings.

Lastly we have another farm table. This one in walnut with a one and a half inch thick top. At nearly 7 feet by 4 feet it is truly a great table.

Lastly we have another farm table. This one in walnut with a one and a half inch thick top. At nearly 7 feet by 4 feet it is truly a great table.

Girder Fork Table Mark II

I decided to make another version of the Girder Fork table. This one has solid “forks” which simplify the joinery and offer new design opportunities. I left a void at the top of the leg to lighten the mass and to give a subtle outside “curve.” It is interesting how the shape changes as you walk around the table or spy it from different parts of the room.

I also changed the apron for this table, that is, it runs the full length of the table. It gives the piece a timeless more familiar feeling.

Lastly I made a new top for the original Girder Fork table, with an asymmetrical arrangement of the boards.

Home Office

We all need a place to work. A place where you can keep all those things you need to get the work done. It’s great if you have a room for the purpose, but you may have to be more versatile. In this case the workspace is combined with the entertainment center.

The left half of this unit is for work. There are file drawers, large and small storage drawers and a pull-out work surface for a keyboard and mouse. Cables run behind the back of the cabinet to reduce clutter. The right half holds a TV, DVD player and video game systems, as well as shelves for books and discs.

The left half of this unit is for work. There are file drawers, large and small storage drawers and a pull-out work surface for a keyboard and mouse. Cables run behind the back of the cabinet to reduce clutter. The right half holds a TV, DVD player and video game systems, as well as shelves for books and discs.

The idea is to have a sliding door that covers one half of this unit depending on which side is in use. The door would have another door in it to allow access to the covered side.

The idea is to have a sliding door that covers one half of this unit depending on which side is in use. The door would have another door in it to allow access to the covered side.

Most of the grain on these walnut cabinets is vertical so I made the drawer fronts run the same way, which makes it feel more modern. I also think its symmetry makes it calming.

Most of the grain on these walnut cabinets is vertical so I made the drawer fronts run the same way, which makes it feel more modern. I also think its symmetry makes it calming.  The work surface also has space inside for the keyboard and more.

The work surface also has space inside for the keyboard and more.

Girder-fork leg

So, I had an idea for a leg design inspired by motorcycle girder-forks (yeah, I know this bike doesn’t have them). I was also thinking about the work of Carlo Mollino, a 20th century furniture designer. The leg could be used on tables, case pieces and chairs. The idea wasn’t to mimic the forks exactly but more to subtly tap into the industrial strength of the shapes.

I liked the simplicity and efficiency of the design, but couldn’t resist the temptation to use more traditional joinery. This made for some tricky mitered mortise and tenon joints. I made full scale model of the leg in poplar first to see how to it would work, and look.

I had some large planks of sepele which would yield a 3 foot by 9 foot table. The planks were 18 inches wide and I wanted to show that so I joined them together with bread-board ends. I used the space between the boards as a design feature and aligned the aprons to allow light through. Placing the aprons in the center also keeps them from hitting your knees.

I hand planed the top and left the faceted marks from the planes for a more lively hewn surface. It just seems warmer and friendlier. The finish is linseed oil and shellac.

It’s hard to photograph this table in our little gallery. I really like the stance and angles down bellow.

I don’t mind mixing styles, good design is good design.